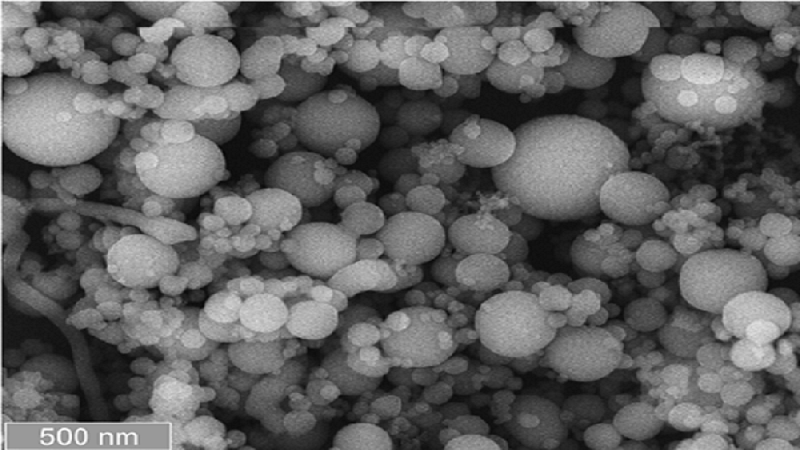

Silica Fume or Microsilica improves concrete

The benefits of using microsilica with cement can be substantial as it reduces thermal cracking caused by the heat of cement hydration mixed with cement and can improve resistance to attack by sulfate and acidic water which further increases the durability of concrete. Advantages and applications are reviewed and original illustrations of several experiments are included.