Japan declearded to construct earthquake proof bulidings :

As an admixture, silica fume has been widely used in the preparation of high-strength concrete…

About Product

About Product

Silica Fume or Micro Silica

Silica Fume or Micro Silica is a undensified admixture which consists primirly very fine amorphous SiO2 particles and meets ASTM C-1240 standards Microsilicais used in ready mix concrete(RMC) and refractory industries

Ca(OH)2 (Free Lime) + SiO2 CSH (Calcium Silicate Hydrate) + H2O

- Silicon Dioxide (SiO2)

- Aluminium Oxide (Al2O3)

- Iron Oxide (Fe2O3)

- Calcium Oxide (CaO)

- Magnesium Oxide (MgO)

- Posphorous (P2O5)

- Carbon (C)

- Potassium Oxide (K2O)

- Sodium Oxide (Na2O)

- Sulfur Trioxide (SO3)

- Chlorine (Cl)

- Moisture (H2O)

Why Silica Fume or Micro Silica is Needed in Concrete?

Micro silica is an extremely fine meterial,with an average diameters 100x finner than cement. This eliminates bleed and the weak transition zone between aggregate and paste found in normal concrete.

- Increases The Modulus of Elasticity

- Increases The Durability of Concrete

- Increases Bond Strength to Concrete

Application Area

Application Area

Here The Applications of

Micro Silica OR Silica Fume

Refractory material usually uses unencrypted micro silicon powder. At present, besides in casting refractory material widely using, unencrypted micro silicon is applied extensively in the fused and sintered refractories.

High Performance Concrete (HPC) containing silica fume has been identified as one of the more important advanced materials necessary in the effort to rebuild the nation's infrastructure. In addition to increased strength and enhanced durability, it produced with silica fume delivers increased toughness, increased resistance to abrasion, corrosion and chemicals, sustainability and life-cycle cost efficiencies. High Performance Concrete Services

any volume of concrete in which a combination of dimensions of the member being cast, the boundary conditions, the characteristics of the concrete mixture, and the ambient conditions can lead to undesirable thermal stresses, cracking, deleterious chemical reactions, or reduction in the long-term strength as a result of elevated concrete temperature due to heat from hydration.

Silica fume is a by-product of the silicon metal/ferrosilicon alloy industry. Collected in baghouse filters, it is a very fine pozzolanic material. The addition of silica fume to concrete was first tested in Norway in the 1950s. Although positive results were recorded in terms of improved strength, at that time no method of retaining large quantities of silica fume was available, preventing its industrial-scale use.

Making full use of micro silica fume concrete early strength, high strength, wear resistance, can build the high grade highway, airport runway, highway tunnel and road repair projects. The construction of roads with silica fume can achieve 25Mpa compressive strength for 12 hours, improve 1 times of abrasion resistance, and 24 hours compressive strength up to 37Mpa, exceeds the design requirement of C20 concrete.

Microsilica or Silica Fume improves the performance of concrete and mortar formulations. It acts physically to optimize particle packing of the concrete or mortar mixture and chemically as a highly reactive pozzolan.

Effects

Effects

Advantages of Using Silica Fume

or Micro Silica

Without Using Silica Fume or Micro Silica

Using Silica fume or Micro Silica

Number talks

Number talks

Prayag will help you get

things complete reality.

Prayag will help you get things complete reality.

Categories

Categories

Silica Fume or Micro Silica Category

Achivements

Achivements

Latest completed projects

High-Rise Building

Architecture

Ready Made Concrete

Architecture

Stone Harbor

Road & Constructions

Highway Fly Over

Road & Constructions

Underground Tunnels

Underground Constructions

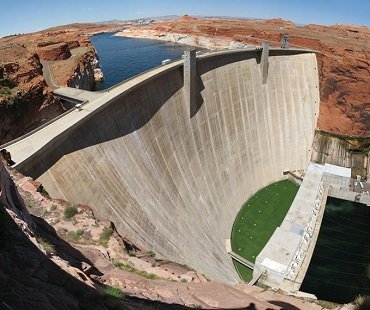

Damp

Damps Reviews

Reviews

Our clients reviews.

Let's talk

Let's talk

Have Any Query?

Office

PRAYAGRAJ CHEMICALS PVT. LTD

MIRZAPUR, GHOSH PARA, PS - BURDWAN, PO - MIRZAPUR,

Dist: Purba Bardhaman, - 713102,

WEST BENGAL, INDIA

News & Blog

News & Blog

Our latest news post

and articles?

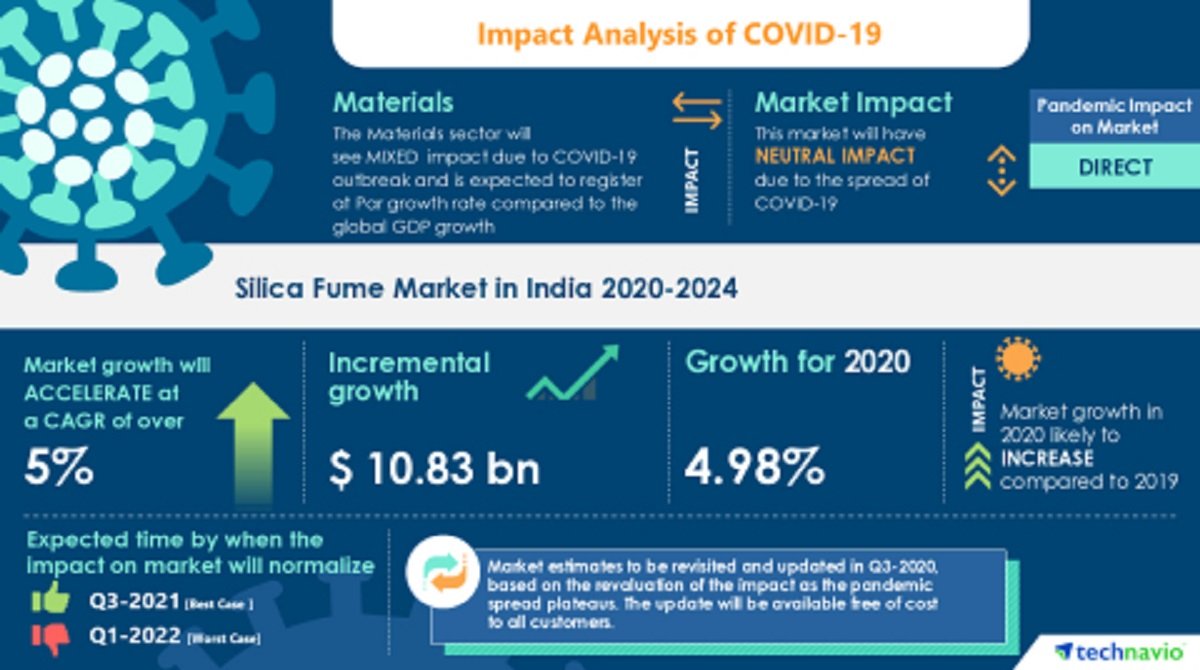

Silica fume market in India and it is poised to grow by USD 10.83 billion during 2020-2024. :

The content of micro silica fume is generally 5% to 10% ...

How much silica fume to add to concrete :

The content of micro silica fume is generally 5% to 10% of cementitious material...

Silica fume VS Fly ash :

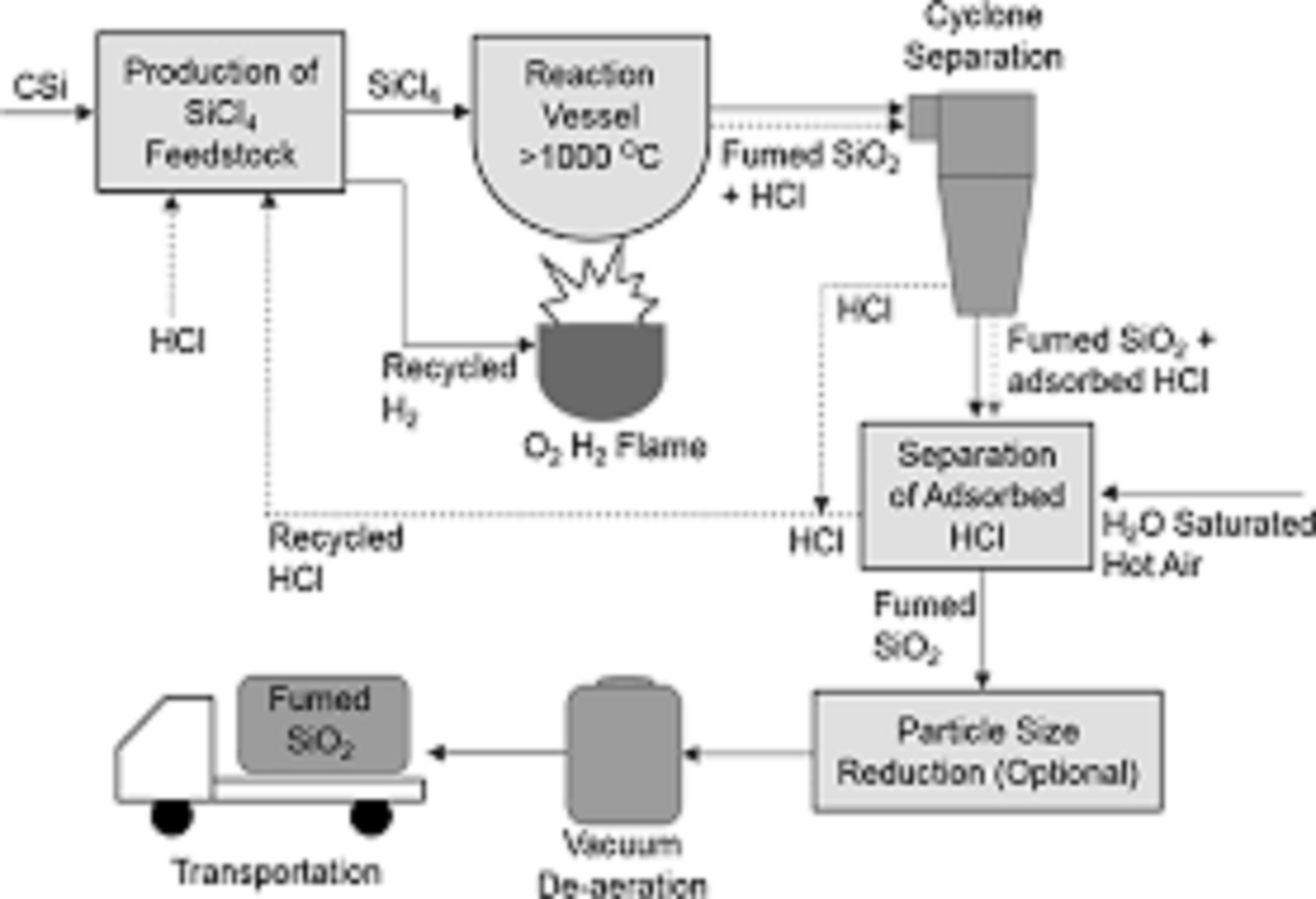

Micro silica, also known as silica fume or agglomerated silica fume, its process is that when ferroalloys in the process of smelting ferrosilicon

The mixture ratio of silicon powder :

The mix proportion design of microsilica fume concrete is mainly based on the design requirements…

Work With Us !

Work With Us !

Have any upcoming project

Are you planning for any upcoming project and in need of our expert support?

Let's discuss in more details.